"Molding the Future of Metal Industries"

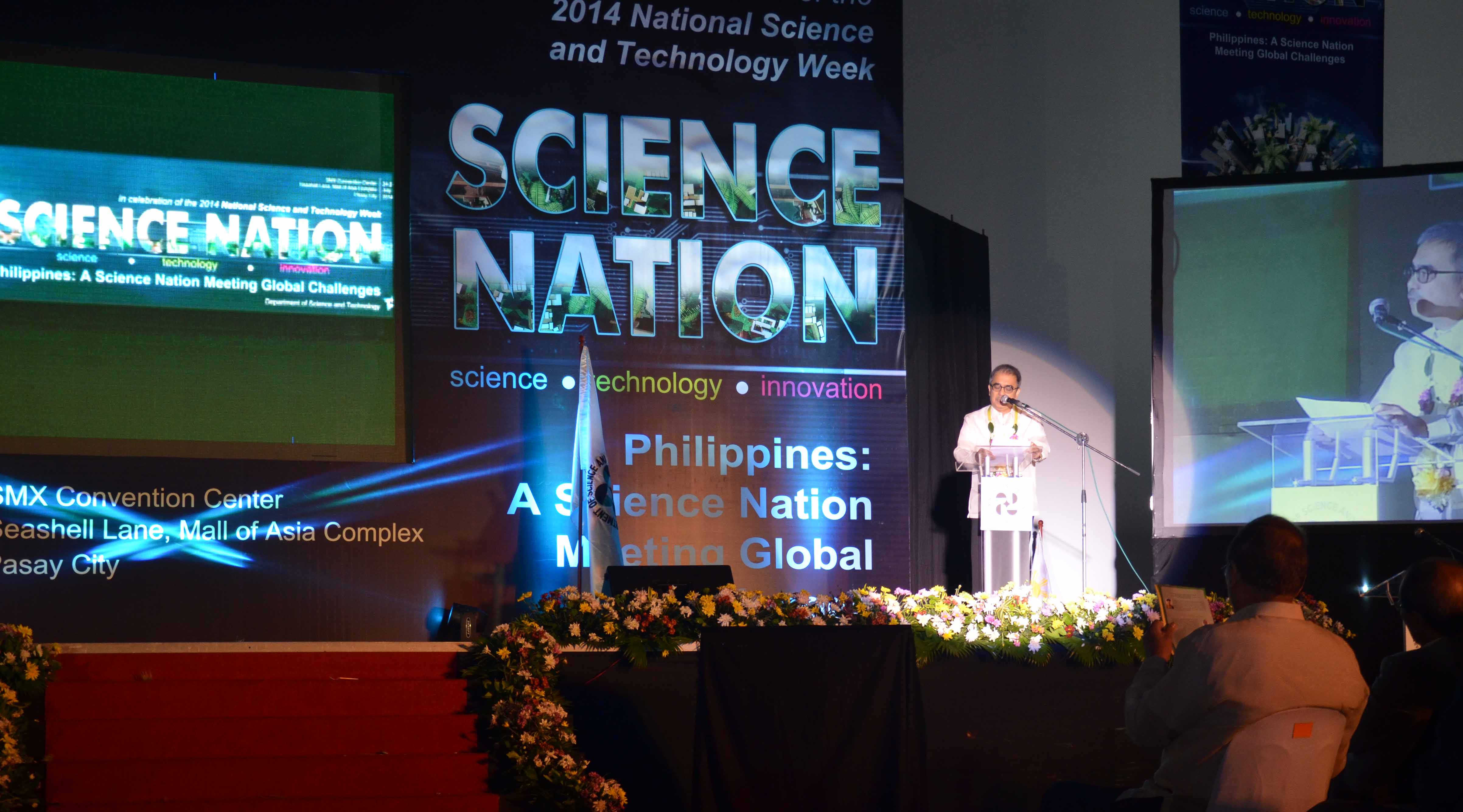

The 2014 National Science and Technology Week (NSTW), held from 24-28 July 2014 at SMX, SM Mall Of Asia, Pasay City was a hit among exhibit viewers and participants. the event aimed to promote the technologies, as well as te services and facilities of the MIRDC and the DOST agencies to everyone from all walks of life. Among the top crows-drwaers in NSTW were the RV-12 plane and the scale-model of the Centrally-powered Hybrid Road Train (CRT), both were featured in Outcome 3.

Secretaty Mario G. Montejo delivered the Keynote Address during the Opening Ceremony. The five-day event is themed: "Philippines: A Science Nation Meeting Global Chalenges." The MIRDC acknowledges unwavering support of the Aerospace Industries Association of the Philippines, especially Famous Secret Precision Machining, Inc. and MOOG Controls Corp. Baguio for providing the materials for the anchor exhibits: an RV-12 airplane (Famous Secret); and Airplane parts, such as actuators and servo valves (MOOG). Also, the outcome 3 centerpiece bought the viewers closer to the DOST's world-class laboratories that are already serving the needs of industries such as the Advanced Device and Materials Testing Laboratory (ADMATEL), One-Stop-Shop Furniture Testing Service, Philippines Genome Centre, and Environment technology Verification (ETV) or Energy Audit.

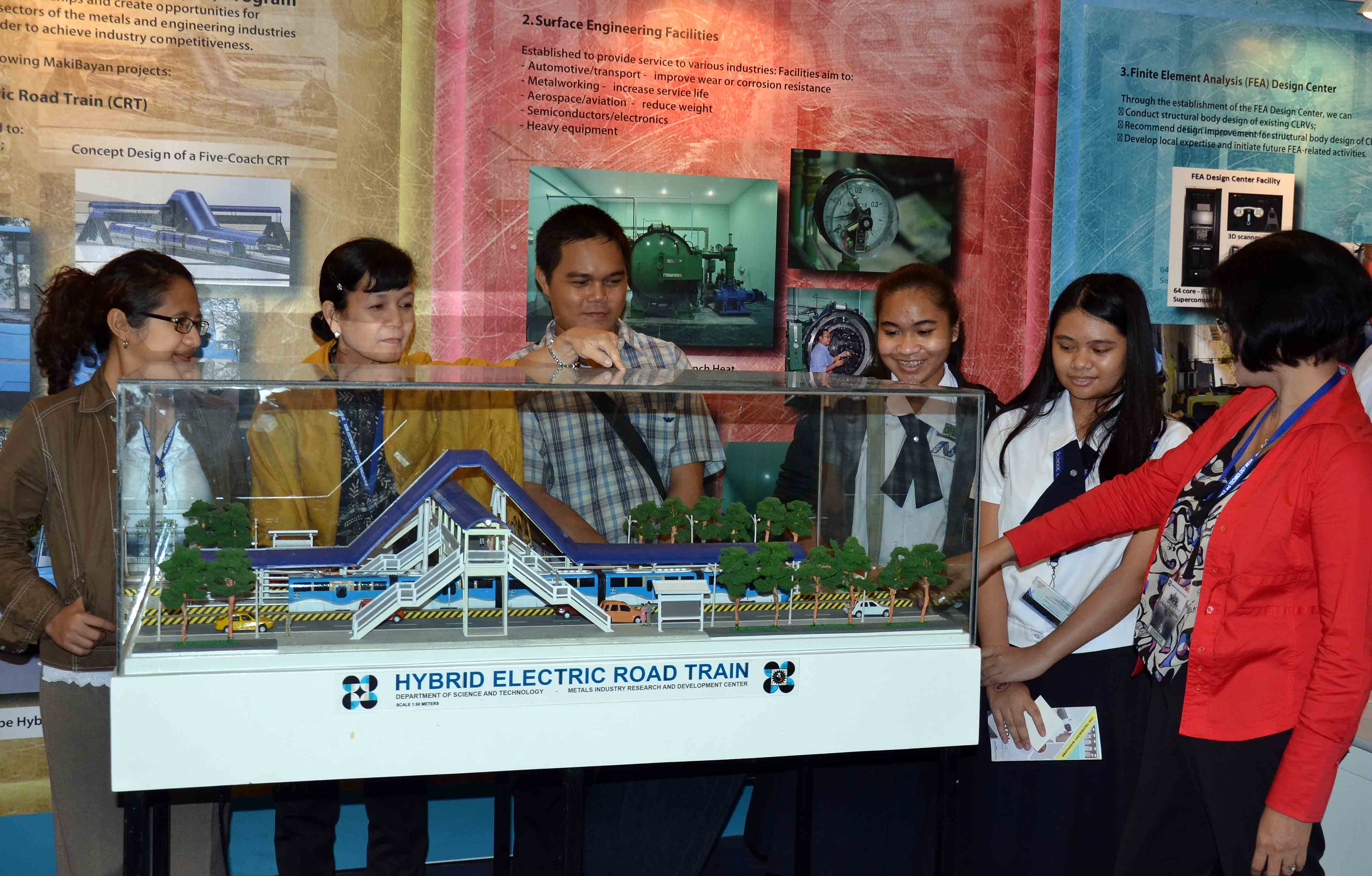

The MIRDC technologies featured the following technologies: Finite Element Analysis (FEA) Design Center; Surface Enfineering TEchnology; Die and Mold Solution Center; and the CRT. Viewers, Participants, Technoacrats and Academicians were very interested and were drawn to the technofora and exhibits.

Sec. Mario G. Montejo and Engr. Robert O. Dizon with PhilMech Executive Director Rex L. Bingabing.

TIPS Staff Ms. Zalda R. Gayahan, teresita C. Villoso and Marlyn U. Ramones explain the CRT to exhibit viewers.

Engr. Rovert O. Dizon, OIC of the MIRDC, wlcomes the participants of the MIRDC technofora.

Ms. Ma. Gracia M. Pelralta of the MPRD discusses the Surface Engineering Technology

Mr. Nelson N. Tumibay of the Materials and Process Research Division (MPRD) presnets the Vacuum Heat Treatment Technology.

Engr. Remartin S. Maglantay o the Prototyping Division talks about Finite Element Analaysis (FEA)

Engr. Joey G. Pangilinan of the MPRD expounds on Surface Engineering Technology

Ms. Lina A. Afable, Chief of the Technology Information and Promotion Section, gives a recall of what has been discussed in the technofora.

"Molding the Future of Metal Industries"

|

The MIRDC proudly celebrated the Metals and Engineering (M&E) week with the holding of the M & E Conference on June 18 with the theme: “Makibayan 2014: Pushing Forward for Industry Competitiveness.” During this special occasion, the MIRDC named Dr. John Hermes D. Bautista of the Philippine Metalcasting Association, Incorporated (PMAI) as the 2014 MIRDC Legacy Trophy Awardee. The MIRDC along with all the champions of the M & E industries are inspired by the accomplishments by the man whom a lot of people call simply as “Mang” Hermes. Dr. Agustin M. Fudolig, Chairman of the M&E Week 2014 highlighted some of “Mang” Hermes contribution to the M&E industries:

In his response message, Dr. Bautista told the audience that Time cannot be regained.” But, according to him, it can be lived through again by remembering – and remembering all the good and pleasant times along with all the frustrations. They can neither be changed nor modified.” The awarding was held at the Auditorium of the newly renovated MWS I Bldg, MIRDC, Bicutan Taguig City. This is MIRDC’s tradition in giving honor to whom honor is due. Just as what is written in the scriptures Romans 13:7: “Render therefore to all their dues: tribute to whom tribute is due; custom to whom custom; fear to whom fear; honour to whom honour.” MIRDC acknowledges all the efforts and hard works of Dr. Bautista that helped the MIRDC attain its mission and vision. The Center with the entire M&E industries salute “The Complete Foundryman” for his valuable contribution to the industry. For him, “to sustain industry growth, we must pay attention to three things: (1) Identify and explore new markets; (2) increase foundry productivity; and (3) improve the whole spectrum of foundry manpower.”

|

"Molding the Future of Metal Industries"

|

On the day of the Lantern Parade at the University of the Philippines Diliman (UPD), the Metals Industry Research and Development Center (MIRDC) Project Management Engineering and Design Service Office (PMEDSO), in collaboration with the UPD, held the first ever demonstration of the Automated Guideway Transit (AGT) System to the public. The demo likewise served as simulation of the use of the AGT ticketing system. It was also the same day that the Road Train, another project spearheaded by the MIRDC under the Advanced Transport Program of the DOST, was launched. |

Sec. Montejo leads the ribbon-cutting ceremony.

The AGT's ticketing system undergoes simulation during the demo run.

UPD Chancellor Caesar Saloma taps the card to gain entrance through the turnstyle.

Joining Sec. Montejo, Asec. Dizon and Chancellor Saloma

AGT were representatives from MIRDC’s industry partners, the academe, and other DOST offices. The ride from station 1 (along C.P. Garcia, near Fine Arts Building) to station 2, which is located along the University Avenue, took approximately one and a half minutes. It was a perfect opportunity to present to the guests that the locally-designed and developed mass transit system is rolling – the realization of a safe and clean mass transport alternative.

The passengers alighted from the AGT at station 2 where the Road Train was waiting to pick them up along University Avenue. The Road Train was also presented to the public, and selected personalities were allowed to board. At this point of its development, it can only accommodate a few seated passengers. It was showcased along with the Public Demo of the AGT so as to let everyone know how the AGT and the Road Train can possibly connect and be of great use for the commuting public. The Road Train is a centrally-powered prototype of hybrid electric road train designed for public transport. It is one of the newest additions to the DOST-MIRDC’s proud R&D outputs. Its development using locally available technology is geared towards addressing pressing national challenges on urban transport. The Road Train travelled the short distance from the AGT’s station 2 toward Quezon Hall. Upon reaching their destination, the passengers were greeted by UP President Alfredo E. Pascual. The DOST-MIRDC is very grateful to the entire UPD officials and staff for the accommodation and support they continually give. Very soon, the two projects will reach completion and the UPD is a big part of the upcoming success.

The AGT (left) and the Road Train (right) are part of the DOST-MIRDC’s Advanced Transport Program that will help solve traffic problems in key cities of the country.

"Molding the Future of Metal Industries"

|

The Metals Industry Research and Development Center (MIRDC) is still accepting applicants for the Training Program on CNC Machine Tool Programming and Operations. The training program is the parallel move of the Department of Science and Technology to the Memorandum Circular No. 02, Series of 2012, issued by the Department of Labor and Employment (DOLE) declaring the CNC machinist skill as a mission critical skill (MCS). With this initiative, the brain drain of CNC skilled workers will be addressed. The current brain drain is a result of CNC machinists, programmers, and operators leaving the country for work abroad. The DOST, through the MIRDC, launched and implemented the project entitled, “Human Resource Intervention for Sustainable Growth and Competitiveness of the Metals and Engineering Sector: Development and Implementation of Appropriate Training Curriculum Design for CNC Machine Tool Programming and Operations.” The project aims to produce 800 trainee-graduates who will fill up the industry’s need for skilled CNC workers. Upon its implementation in late 2012, the CNC Training Program has been conducted in various selected regions of the country. The project’s progress is summarized in the lists below. a. List of graduates and on-going batches (20 pax per batch) in different regions

b. List of Partner Support Organizations (PSOs) 1. Technical Education and Skills Development Authority (TESDA) Regional Training Centers o CAR (Baguio) 2. Western Visayas College of Science and Technology c. List of Sponsoring Firms (Industry Immersion) 1. Parts Phils. The training program will run until December 2014. The MIRDC is accepting applicants for training to fill in the needed number of graduates as an answer to the M&E industries’ workforce requirements. - High School graduates with machining course from TESDA or TESDA-accredited training institutions; Training is free for unemployed participants. A daily stipend of P300.00 will be provided to unemployed trainees for the entire duration of the CNC Training Program. |