DOST-MIRDC Seeks Inputs from SBSR Industry and MARINA Representatives Located in Region VI for its Study Focused on Determining Science and Technology-Based Interventions Required by the Shipbuilding and Ship Repair Industry

By Kai H. Negado

Iloilo province in Region VI is the most recent destination of the industry study team of the Department of Science and Technology - Metals Industry Research and Development Center (DOST-MIRDC) as it conducted its fifth consultative meeting with players in the shipbuilding and ship repair (SBSR) industry.

The multiple issues raised by shipyards in Region VI, as well as by Regions, III, VII, IX, and NCR which were previously visited by the industry study team, stem from the lack of course offerings and training for human resource development as required by the SBSR industry.

Held on July 18, 2023, the consultative meeting was attended by representatives from Region VI SBSR companies, John B. Lacson Foundation Maritime University, the Maritime Industry Authority (MARINA) Region VI, and DOST Region VI. Those in attendance were agreeable with the study findings shared from previous meetings, especially the need for capability building of the existing workforce in the SBSR industry, and software acquisition and training.

DOST-MIRDC team presenting their current findings during the consultative meeting on July 18, 2023

While it is true that software acquisition and lack of training on CAD software are major challenges, Mr. Noel Lucero, General Manager of Jagnee SBSR and Jagnee Fishing Corp., said “the main problem is kulang ng NAME dito,” pertaining to the lack of naval architects and marine engineers (NAME). Graduates of NAME courses are few, most probably since it is not a widespread undergraduate course in both popularity and because of its limited course offerings from tertiary schools nationwide.

Naval architects and marine engineers help design, construct, and maintain ships, boats, and other surface and subsurface water vessels and structures - expertise that our SBSR industry lacks.

Engr. Rufina A. Aquino, Officer-in-Charge of MARINA Region VI, concurred with Mr. Lucero’s statement, adding to the fact that MARINA strongly prefers hiring NAME graduates as additional manpower for its current expansion. Ms. Aquino also stated that NAME graduates are scarce, which results in MARINA Region VI hiring NAME graduates from Metro Manila and Cebu.

In an effort of the DOST-MIRDC to continuously innovate and improve its programs and projects through science and technology-based interventions, the Center provided a platform to convene directly with its stakeholders, specifically those in the SBSR industry. Challenges that arise during these consultative meetings will serve as inputs to the industry study being conducted by the DOST-MIRDC which aims to present an overview of the country’s SBSR industry and how the Center may contribute to its advancement.

Updates and other details of the ongoing study focused on the SBSR industry as well as on the services offered by the DOST-MIRDC are available via the DOST-MIRDC Facebook page and official website www.mirdc.dost.gov.ph.

Enhancement of Technical Skills for Die and Mold Companies Get a Boost from DOST, PEZA, and PDMA, Inc.

By: Ella Vanesa L. Lopez

Gen. Trias, Cavite – The partnership between government and private sector shined bright as the Department of Science and Technology-Metals Industry Research and Development Center (DOST-MIRDC), Philippine Economic Zone Authority (PEZA), and the Philippine Die and Mold Association, Inc. (PDMA, Inc.) held the “Mold Technology Demonstration, Appreciation, and Promotion, A Meet-and-Greet with the Media” at the Mold Technology Support Center (MTSC) on July 20, 2023. This event is a strategic campaign to promote the services of the MTSC as the project nears its completion.

“We want the MTSC to be sustainable, we want it to be relevant, and we want it to be utilized by our partners and local industries. Hopefully, many of our local companies will be aware of MTSC and appreciate the services it can offer,” stated Engr. Robert O. Dizon, Executive Director of the DOST-MIRDC.

Dir. Robert O. Dizon of DOST-MIRDC delivering his welcome remarks

DOST-MIRDC is the lead implementing agency of the ‘Establishing the Mold Technology Support Center’ project, which is an Official Development Assistance (ODA) grant of the Republic of Korea. Collaborating with the DOST-MIRDC for the MTSC project are the PEZA, Department of Trade and Industry- Board of Investments (DTI-BOI), and PDMA, Inc.

In her speech, Atty. Tanyag called for all stakeholders to collaborate with the MTSC and utilize its services, “For the success and sustainability of this project, we’ll need the support of stakeholders, this is by encouraging those in the mold and die industries, especially those inside and outside the PEZA zone, to avail of the training provided by the MTSC.”

Mr. George Ong of PDMA commended the contributions of all agencies and organizations involved in this project, “We know that there are many challenges in the manufacturing industry, but with the help of DOST-MIRDC, DTI-BOI, and PEZA, we can reach greater heights moving forward.”

(T) Atty. Norma B. Tanyag of PEZA and (B) Mr. George Ong of PDMA reacting to the testimonies of MTSC clients

The event was attended by members of the media, private companies, academe, and government organizations. A number of representatives from the private sector are clients of the MTSC, and they shared their testimonies about how the services they availed of from the MTSC contributed to the improvement of their skills.

Guests of the promotional event entitled “Mold Technology Demonstration, Appreciation and Promotion, A meet-and-greet with the media”

Recalling his experiences working with the MTSC, Engr. Charlie Buenaventura, Production Supervisor at McBride Corporation, cited the benefits of availing of the MTSC’s services, he said, “Nung training namin, kami rin ang nagtutroubleshoot kapag nakakaencounter kami ng defects na commonly naeencounter namin sa planta. Ang mas maganda nito, napakaadvance ng mga technology ng MTSC kaya natuto talaga kami.”

The MTSC offers training programs and is open to clients for time sharing and actual time use of equipment. Through these services, the MTSC is supporting the growth of the economy by boosting the capabilities of the local die and mold industry.

The MTSC project officials recognize that the MTSC’s sustainability will be further ensured with the continued support of its clients and stakeholders. This promotional event is a way for DOST-MIRDC, through its media partners, to spread the word about the MTSC as far and wide as possible.

DOST Balik Scientist Dr. Caldona: How to Make Polymeric Materials ‘Speak’

by Faith P. Macatangay

“You can’t talk about materials without talking about polymers. Now is the polymer age.” – Dr. Eugene B. Caldona

A polymer is any natural or synthetic large molecule made by repeating small molecules called monomers. Polymerization is the process that links monomers together using heat and pressure.

We all use polymers - in fact, a famous example of these are the plastics that we use daily.

Plastic is a synthetic polymeric (made of polymers) material derived from crude oil and natural gas. Plastics became the name of polymers because of their booming demand across almost every sector, including packaging, building and construction, consumer products, transportation, and industrial machinery.

The techniques for measuring polymers' properties were the center of DOST Balik Scientist Dr. Caldona’s seminar entitled ‘Conventional and Modern Approaches to Characterizing Polymeric Materials’ on July 12, 2023.

In purchasing polymers to be used, Dr. Caldona shared that researchers must consider fundamental properties such as molecular weight and distribution. The minimum molecular weight for good physical and mechanical properties for the most important polymers is 25,000 grams per molecule. In measuring molecular weights, he highlights the commonly used Gel Permission Chromatography (GPC) analysis and the detectors used in its system.

Polymers have other properties that influence their characteristics. Making polymers ‘speak’ is like asking them what their properties are so that they can be understood and used in appropriate applications.

Crystallinity is one of their properties. It refers to the alignment of molecular chains, which influences the hardness of polymers. X-ray diffraction (XRD) can determine a sample's degree of crystallinity.

Chemical structure is another property of polymers. Dr. Caldona shared some spectroscopic techniques to probe the chemical structures of polymers: infrared (IR) spectroscopy to measure the interactions between molecules and IR light; Surface-Enhanced Raman Scattering (SERS) spectroscopy for finding the functional groups of atoms or bonds that are not seen using IR spectroscopy; and X-ray photoelectron spectroscopy (XPS) to identify the quantitative atomic composition and chemistry.

The behavior of polymers under controlled temperature programs is also part of a better understanding of polymer performance. Thermal analysis techniques include

thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). TGA measures the changes of sample mass with temperature or time under programmed

temperature. DSC, on the other hand, measures the energy absorption of a sample as it is subjected to a specified thermal profile.

The resource person, Dr. Eugene B. Caldona, discusses to the onsite and online participants.

According to Dr. Caldona, “in terms of resistance to fracture, it is always very useful to fabricate polymer composites for demanding applications.”

The resistance to fracture of polymers is comparable to that of metals, ceramics, and composites. Other mechanical behaviors, such as strength and toughness, can be increased by incorporating different materials into polymers, such as composites and rubber.

The DOST Balik Scientist further shared that the relationship between the change in mechanical properties and temperature of the polymer can be determined using thermomechanical characteristics analysis (TMA). Rheology, meanwhile, measures a material's flow behavior through an oscillatory test mode.

In summary, the discussion imparts to the participants that performing the recommended techniques to assess the characteristics of polymers is an advantage in synthesizing or fabricating polymeric materials.

This seminar was the third of the five-part seminar series of Dr. Caldona about materials engineering. The seminars were in connection with Dr. Caldona’s engagement with the DOST-Metals Industry Research and Development Center as a DOST Balik Scientist.

Visit the DOST-MIRDC's Facebook page for regular updates about the Center’s activities that enhance skills of the metals, engineering, and allied industries.

DOST Balik Scientist Dr. Caldona’s Works Focuses on Corrosion Science; Shares to Fellow Researchers

by Faith P. Macatangay

Dr. Eugene B. Caldona’s stint as a DOST Balik Scientist may have been short, but truly very sweet. Thanks to the series of webinars he conducted, external participants, as well as the researchers at the DOST-MIRDC, learned much about surface engineering.

Dr. Caldona brought his laboratory closer to Filipinos as he shared his group’s research projects and activities during the last of the five-part seminar series entitled ‘High Performance Thermosets, Semi-Fluorinated Polymers, Thin Films, Composite Coatings, and 3D Printed Materials,’ held on July 17, 2023.

Dr. Caldona gave a brief background on the State of Dakota in the United States of America, the North Dakota State University, and its Department of Coatings and Polymeric Materials, where he is currently affiliated as an Assistant Professor. He also shared about his research group that specializes in the fabrication of advanced protective coatings, the development of new groups of coating materials and corrosion-preventing materials, and the utility of electrochemical approaches to evaluate the protection efficiencies of coating materials.

By definition, corrosion is the deterioration of a substance of its properties as a result of an undesirable reaction with the environment. Dr. Caldona emphasized that “the damage we encounter from corrosion can be minimized by using a coating that can function as a layer of physical barrier.” According to Dr. Caldona, this coating serves as a protection by slowing down the transport of aggressive substances that harm and damage metal surfaces.”

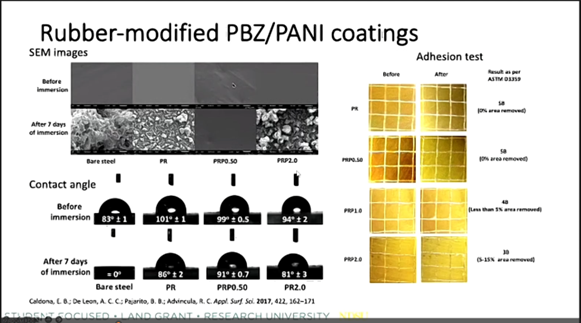

In his presentation, he enumerated the following coatings to minimize corrosion: organic polymer coatings, stand-alone polymer barrier coatings, and additively manufactured coatings.

Organic polymer coatings are the most widely used corrosion barriers due to ease of application, high-performing capabilities, and effective functionalities. Adding micro and nano-size fillers can further enhance the overall coating performance. Their surface may also be roughened to improve the anti-wetting properties of coatings.

Stand-alone polymer barrier coatings are also utilized because of their simplicity and ease of preparation. They are proven effective as they act as an insulating layer that blocks electron transfer between the metal and corrosive medium to prevent the electrochemical oxidation process.

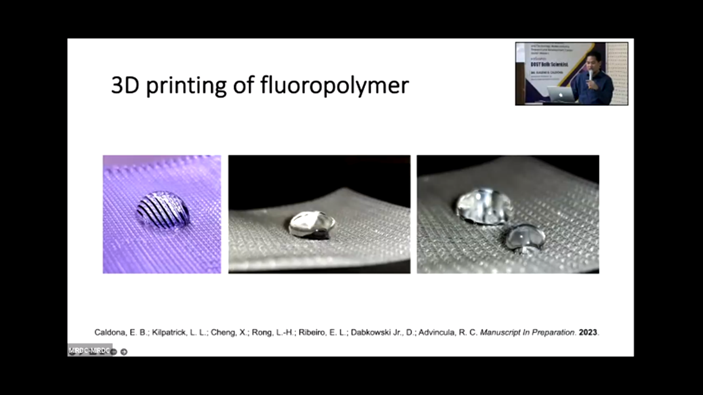

Additive manufacturing or 3D printing was also applied for coating purposes. 3D printing in coating preparation is beneficial mainly due to its automation and digital design availability. The 3D printing approach helps solve failures in many coating materials.

A slide presented by Dr. Caldona shows the results of a study about rubber-modified polybenzoxazine-based (PBZ)/ polyaniline (PANI)coatings. PBZ is an example of an organic polymer coating.

Meanwhile, corrosion inhibitors are different from coatings. These compounds are added in minimal quantity to a corrosive medium to slow down the corrosion rate - their inhibiting abilities lie in their molecular structure and ability to absorb and form a protection barrier across the metallic surface. Organic compounds that contain combinations of sulfur, oxygen, phosphorus, nitrogen, aromatic rings, and multiple bonds have been shown to function effectively as corrosion inhibitors.

Superhydrophobic surfaces are applied for the best possible protection of metals from being rotten. They stand out due to their anti-wettability property. Only two requirements are required to achieve super hydrophilicity – surface roughness on micro and nanoscale and low surface energy materials.

“[In] Every research that deals with coatings, [it] is important to consider the effect of damages on the coating and integrity and performance during their intended use,” Dr. Caldona noted.

The resource person, Dr. Eugene B. Caldona, discusses to the onsite and online participants.

To know more about the research and development activities and the trainings and seminar offerings of the Center, visit the DOST-MIRDC’s website and Facebook page.

DOST Balik Scientist, Unimpressed by 3D Printing Years Ago But Amazed at How It Is Making Waves in Various Industries Now

By: Ella Vanesa L. Lopez

“Ten years ago, sabi ko isip ko, ‘ano naman ang magagawa ng 3D printing na ‘to sa research?’ I was looking at 3D printing from a chemist’s point of view. Eh, para sa mga hobbyist lang ito, but look at what happened now. May AMCen tayo at marami na ring papers ang napa-publish sa 3D printing.”

Dr. Eugene Caldona mentioned this fond memory during his presentation on "Additive Manufacturing of Engineering and High-Performance Polymeric Materials" on July 13, 2023. The DOST Balik Scientist shared his perception then of additive manufacturing (AM) impacting product development far-off from reality.

Official poster for Dr. Eugene Caldona’s talk on “Additive Manufacturing of Engineering and High-Performance Polymeric Materials.”

Façade of the Advanced Manufacturing Center (AMCen) of the DOST-MIRDC, the largest 3D printing facility in the country.

AM or 3D printing technology was first introduced in the 1980s, and has significantly advanced in recent years. 3D printing is now being utilized to create simple do-it-yourself items as well as large-scale structures such as a house or a building. This just clearly shows that there is no limit to technology.

Dr. Caldona explained all about the different high-performance materials that are now being used in 3D printing during his talk.

Dr. Caldona discussed polymers and the rising trend of AM across the globe. Further, he talked about the challenges and tips on how to effectively 3D print high-performance materials, which include polyetheretherketone (PEEK), polyphenylene sulfide (PPS), Kevlar, polypropylene, fluoropolymer, and Epoxy-based materials.

The Philippines has ventured into AM to be at par with its ASEAN neighbors, who have long been implementing this technology. A manifestation of the country’s venture into AM is the Advanced Manufacturing Center (AMCen) of the Department of Science and Technology – Metals Industry Research and Development Center (DOST-MIRDC). The AMCen embarks on initiatives to enhance the aerospace, defense, biomedical, healthcare, and automotive industries, among others, through 3D printing.

Dr. Caldona expounded on the different polymers that are currently being used by the 3D printing industry, some of which are also offered by the AMCen. In AMCen, clients have a variety of materials to choose from depending on their requirements, such as (1) Standard Polymers: polymethylmethacrylate (PMMA) standards, polyvinyl chloride (PVC), polystyrene (PS), polyethylene terephthalate (PET, PETE, PETG), acrylonitrile butadiene styrene (ABS), and polypropylene (PP); (2) Engineering Polymers: polycarbonate (PC), thermoplastic polyurethane (TPU), and polyamides (PA) or nylon; and (3) High-Performance Polymers: polyethyleneimine (PEI), and polyetherketone (PEEK).

Some of the different additive manufacturing technologies that are available at the Advanced Manufacturing Center (AMCen).

According to Dr. Caldona, the rapid and systematic fabrication approach offered by this cutting-edge technology is what commonly appeals to people. However, others might not realize that 3D printing will not only accelerate the product development phase but also improve supply chain efficiency.

The continuous rise of the use of 3D printing for research, innovation, and manufacturing is now very obvious and very different from what Dr. Caldona perceived many years ago. Soon, more people are expected to create things differently from the conventional methods that we are used to.

The recently concluded seminar is the fourth in the seminar series by Dr. Caldona for the DOST Balik Scientist Program (DOST-BSP). The DOST-BSP encourages Filipino experts abroad to return home and impart their expertise in order to foster the advancement of science, technology, and innovation in the country. Dr. Caldona’s engagement with the DOST-MIRDC as a DOST Balik Scientist is focused on the Center’s Surface Engineering R&D Program.