Balik Scientist Program: Solidifying Dreams of Modernization for the Philippine Nation

By: James Bernard Herrera

Balik Puso, Balik Pilipinas, Balik Scientist! Filipino experts from various fields have been leaving our home country for decades in hopes of attaining greater heights in their careers. As time went by, in an attempt to ease the burden on the country’s development, the Philippine government took the initiative to establish the Balik Scientist Program (BSP). While it was enacted back in 1975, it was formally institutionalized as the Republic Act 11035 in 2018.

This program serves to be a stopgap, counteracting the effects of brain drain in the country. BSP promotes the local circulation of information and knowledge that Filipino experts from abroad have gained from their years of practice, which strengthens the science and technology capabilities of the Philippines. Knowledge and information transfer also accelerates the flow of technology within public and private industries, the academe, and government institutions, which guarantees progress in various fields.

BSP also provides incentives to the returning Filipino experts, on top of their chance to serve as pioneers of innovation in their home country. According to Executive Director Enrico C. Paringit of the Philippine Council for Industry, Energy, and Emerging Technology Research and Development (DOST-PCIEERD), the program had successfully connected with 157 Balik Scientists since 2013, all of which came to impart their experiences and learnings in different sectors. At present, there have been a total of 664 successful BSP engagements since the year 1975.

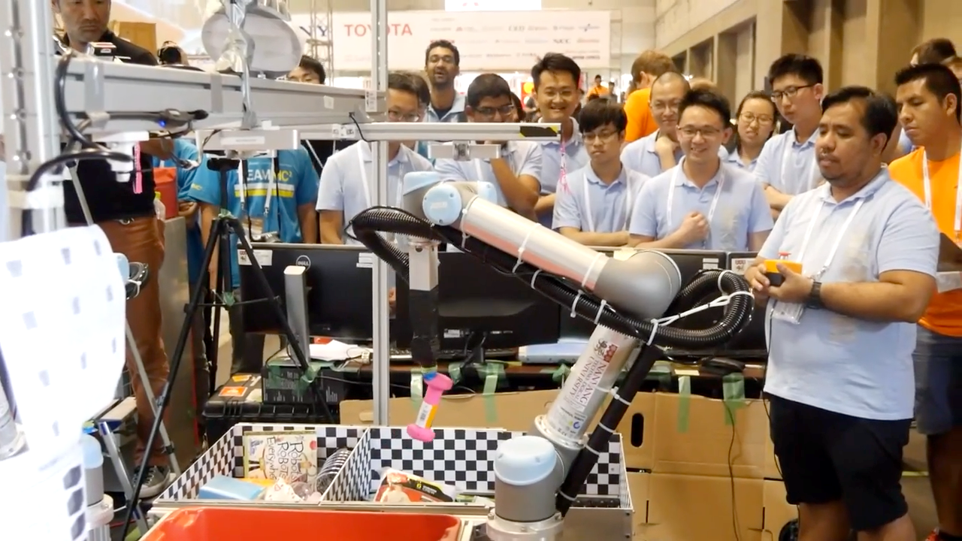

Among the experts that the BSP has brought back to the country, one of them specializes in robotics. Dr. Albert Causo, CEO and co-founder of Hand Plus Robotics based in Singapore, who is also the second Balik Scientist who became associated with DOST-Metals Industry Research and Development Center (DOST-MIRDC), did a short-term engagement where he worked with Dr. Jayson Rogelio from Advanced Mechatronics, Robotics, and Industrial Automation Laboratory (MIRDC-AMERIAL). Prior to his BSP engagement, he mentioned that he chose to do the short-term option which he considers as the “getting to know” stage of this program, and will later decide his next course afterwards.

At the end of his program term, Dr. Causo had his exit presentation in the morning of September 16, 2024. His presentation titled “Are We Ready for Robots? Opportunities and Challenges for Robotics in the Philippines” laid bare the current reality of robotics in the country. “In summary, we need to catch up”, he said as he went straight to declaring the findings of his study. In relation to this, Metals Industry Research and Development Center (MIRDC) Executive Director Robert O. Dizon stated, “there’s not much activity in automation. What’s lacking? Expertise in robotics.”

Showcasing of robotic arm by Dr. Causo in his presentation (Source: Dr. Albert Causo)

Following this, Dr. Causo said that back in December 2023, he met with Executive Director Paringit where one of their discussions included that he was hoping to put up a subsidiary of his company in Singapore here in the Philippines. However, he decided to let go of the idea after learning that the country lacks qualified robotics engineers for the company to operate, and opted to go for Malaysia instead.

This missed opportunity highlights the challenges our country is facing in this field of expertise, but mentioned that he can still see its potential in the near future. At present, Dr. Causo is the Program Director of ALGOrhythm Robotics Center in Cebu City where they guide and train the younger generations in the field of robotics. “The best age is to start them young; slowly introduce them to technology that they can handle… let them learn the skills needed to not be afraid.”

On a similar note, Director Dizon had a training agreement with Dr. Causo where MIRDC personnel were sent to Malaysia to train under his wing. This is in hopes of upscaling the capabilities and skills of engineers in AMERIAL, which will bolster the services that MIRDC has to offer.

Dr. Causo as he tells the story of his experience as a Balik Scientist with AMERIAL

Moving further, despite the difficulties in adapting robotics on a large scale level, Dr. Causo showcased some robot related patents here in the Philippines. These creations are being used in the fields of medicine, search and rescue, environment protection, agriculture, and so on.

As the presentation came to a close, Dr. Causo expressed his satisfaction in being one of the growing Balik Scientist community. “I can say that we have a future together after experiencing the Balik Scientist Program.” He sees BSP as the start of potential future partnerships between him and the MIRDC, stating that he is looking forward to introducing the center to foreign companies that he worked with, including the Singapore Institute of Manufacturing Technology.

To conclude, DOST’s Balik Scientist Program is a doorway of possibilities waiting to be opened by our fellow Filipinos who excelled in their own field. Not only does it let new knowledge flow into the local community, but also lets these scientists return to the place they can truly call home. Those who spread knowledge that can improve the livelihood of the people are among those that we call modern day heroes.

Balik Scientist Program: Driving Force of Innovation for the Filipinos, by Expert Filipinos

By: James Herrera

Filipino experts from various fields have been leaving the Philippines for decades in pursuit of greater opportunities abroad. To address the impact of this brain drain on national development, the Philippine government established the Balik Scientist Program (BSP). This initiative promotes the return of Filipino experts to share the knowledge and skills they have gained overseas, fostering the local exchange of ideas and expertise.

Since the inception of BSP in 1975, the program has successfully engaged 664 Balik Scientists from various fields of expertise, including Dr. Albert Causo, an expert in robotics. Dr. Causo is the CEO and co-founder of Hand Plus Robotics in Singapore. He is also the second Balik Scientist to form a partnership with DOST-Metals Industry Research and Development Center. During his short-term engagement under the BSP, he collaborated with DOST-MIRDC’s Advanced Mechatronics, Robotics, and Industrial Automation Laboratory (AMERIAL).

Screenshots taken during Dr. Causo’s Exit Presentation

At the conclusion of his BSP engagement, Dr. Causo delivered an exit presentation titled “Are We Ready for Robots? Opportunities and Challenges for Robotics in the Philippines” on September 16, 2024, via Zoom. In his presentation, Dr. Causo candidly assessed the state of robotics in the Philippines, noting, “In summary, we need to catch up.”

Despite the country’s difficulties in adapting robotics on a large scale, Dr. Causo remains optimistic, viewing the situation as an opportunity for growth and innovation. He highlighted existing robot-related patents in the Philippines, with applications spanning medicine, search and rescue, environmental protection, and agriculture.

In line with exploiting opportunities for growth and innovation, the DOST-MIRDC completed the Internet of Things (IoT)-based Machine Shop Monitoring System project. This low-cost machine monitoring system determines machine utilization which is an important performance parameter of a manufacturing facility. As this system is designed to be low-cost, it can be used by small companies. This locally designed and developed system is now available for commercialization and can serve as a stepping stone for local companies’ upgrade toward Industry 4.0.

The DOST-MIRDC’s efforts to prepare local manufacturing firms for Industry 4.0 is a parallel move toward preparing them for robotics and the multitude of benefits that come with the use of this technology.

Currently, Dr. Causo serves as the Program Director of ALGOrhythm Robotics Center in Cebu City, where he helps train and guide the next generation of robotics enthusiasts. He hopes to continue contributing to the advancement of robotics in the Philippines and sees his stint as a Balik Scientist as the foundation for future collaborations with DOST-MIRDC. Dr. Causo is also eager to introduce the Center to international partners, including those at the Singapore Institute of Manufacturing Technology.

The DOST’s line agencies, especially DOST-MIRDC, encourage all Filipino experts abroad to join the growing roster of Balik Scientists who have greatly contributed to advancing science, technology, and innovation in the country.

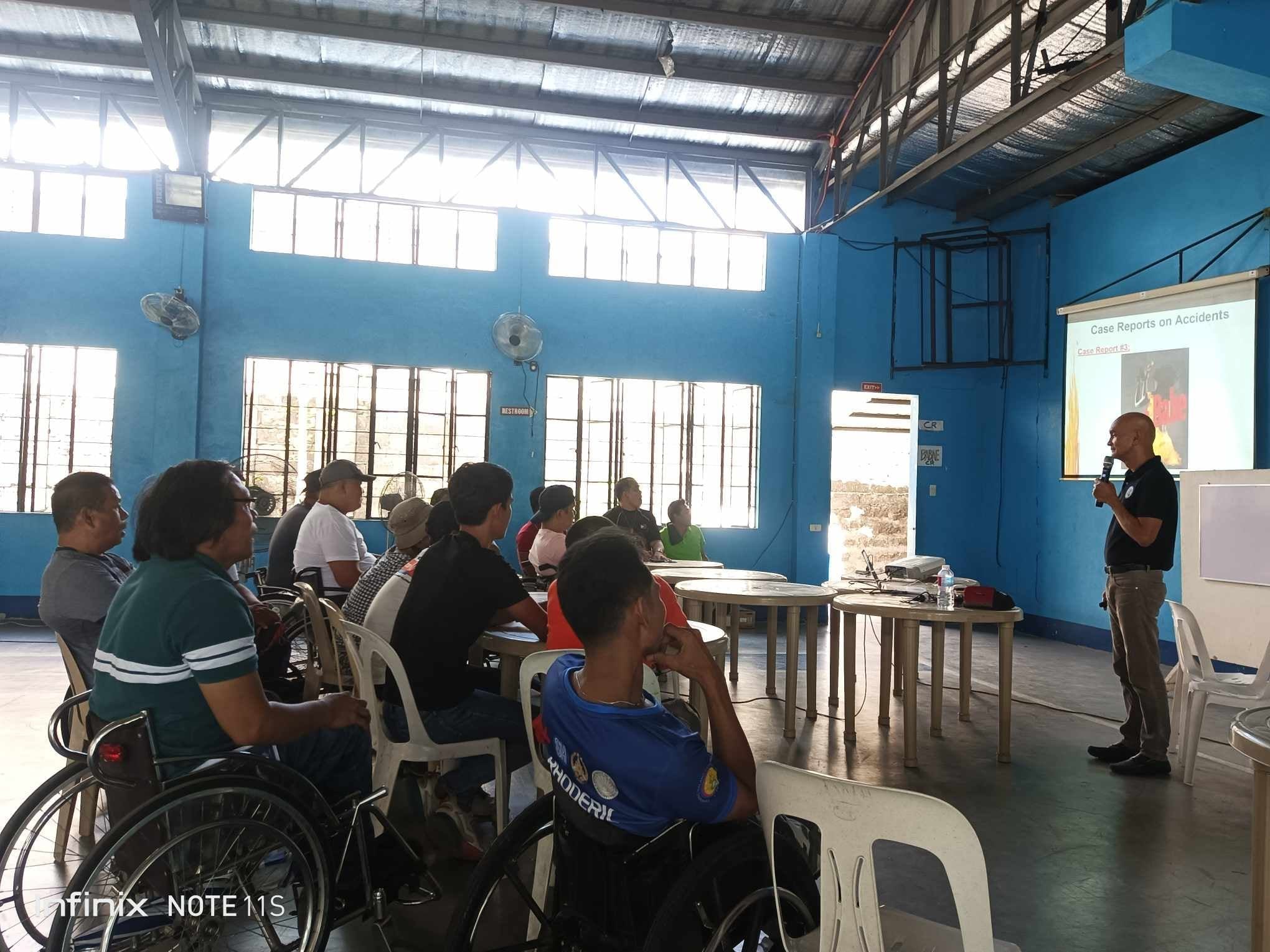

Empowering Abilities: DOST-MIRDC and Philippine Welding Society Host Inclusive Training Workshop

By: Ella Vanesa L. Lopez

In celebration of National Disability Rights Week, the Department of Science and Technology - Metals Industry Research and Development Center (DOST-MIRDC) partnered with the Philippine Welding Society (PWS) to provide specialized training to 15 differently-abled individuals at Tahanang Walang Hagdanan, Inc.

Tahanang Walang Hagdanan, Inc. (TWHI), a non-profit organization, is committed to enhancing the lives of differently-abled individuals by providing skill development, employment opportunities, and promoting greater independence and social integration through diverse services and programs.

On July 19, 22, and 23, 2024, participants from TWHI received training in welding safety procedures, sheet metal layout development, and materials inspection and evaluation. Participants acquired practical skills that will significantly improve their ability to create high-quality metal products, such as custom-designed wheelchairs. With improved skills, they now have increased potential to be more productive and employable.

DOST-MIRDC and PWS provided skills training at TWHI on July 19, 22, and 23, 2024 on the following topics: Sheet Metal Layout Development (top), Non-destructive Testing (middle), and Welding (bottom).

“Napakalaking tulong kaalaman [ng mga training] para sa aming [mga] manggagawa,” said Mr. Domingo Literal, Production Director at TWHI. “Malaking tulong para ma-maximize ang output ng mga materials [at] akmang-akma sa araw-araw na trabaho sa wheelchair production.”

Initiatives such as this training program not only equip differently-abled individuals with valuable skills but also highlight their incredible potential and capabilities, “Matagal na nating partner at tinutulungan ang Tahanang Walang Hagdan,” said DOST-MIRDC’s Industrial Training Section Chief, Mr. Reynaldo L. dela Cruz Jr. “noon pa man din ang assessment natin sa kanila, ay meron na talaga [potential]… more on upgrading and additional knowledge na lang.”

By fostering inclusivity and empowerment, TWHI, DOST-MIRDC, and PWS are making significant strides towards a more inclusive society where everyone can contribute and thrive.

For more information about DOST-MIRDC’s training programs, including regular, packaged, and regional trainings, please contact This email address is being protected from spambots. You need JavaScript enabled to view it..

DOST hands over Metals and Engineering Innovation Center to Ifugao State University to advance innovation in the Cordilleras

LAMUT, IFUGAO, 7 August 2024 – Local businesses, students, educators, and researchers in the Cordillera Administrative Region (CAR) can now explore opportunities for invention and innovation through the technologies available at the Department of Science and Technology (DOST)-funded Metals and Engineering Innovation Center at Ifugao State University (IFSU) Lagawe Campus.

Leading the handover ceremony is DOST Secretary Renato U. Solidum Jr., who emphasized the transformative potential of the Innovation Center. “This Center will provide our engineers, researchers, and industry professionals with access to advanced tools, facilities, and expertise… It will also serve as a collaborative platform where ideas can be exchanged, solutions can be developed, and new technologies can be incubated.” said Sec. Solidum.

DOST Secretary Renato Solidum Jr. delivering his speech.

The establishment of this Innovation Center is part of a national strategy to enhance regional capacities for knowledge and technology generation. Implemented by the DOST through one of its research and development arm, the Metals Industry Research and Development Center (DOST-MIRDC), this initiative underscores the department's commitment to promoting science, technology, and innovation (STI) across the country.

“We realized that we are not doing enough. We are supposed to be serving the whole country. The Metals and Engineering Innovation Center has been doing what MIRDC should be doing in the regions. With this event, we are not just turning over the facility; we are sharing with you our vision and mission,” stated Engr. Robert O. Dizon, Executive Director of DOST-MIRDC on fulfilling the DOST-MIRDC’s dream of putting up DOST-MIRDCs in Luzon, Visayas, and Mindanao.

From left to right: IFSU President, Dr. Eva Marie Codamon-Dugyon; DOST-CAR Regional Director, Dr. Nancy Bantog; DOST-MIRDC Executive Director, Engr. Robert Dizon; DOST-MIRDC Deputy Executive Director, Dr. Agustin Fudolig; DOST Secretary, Dr. Renato Solidum, Jr.; Undersecretary for Regional Operations, Engr. Sancho Mabborang; and Assistant Secretary for Development Cooperation, Mr. Rodolfo Calzado, Jr

IFSU President, Dr. Eva Marie Codamon-Dugyon, expressed her enthusiasm about the partnership and in their commitment to bringing metals and engineering innovation to the whole region. "We are immensely grateful…the MEIC is a transformative initiative not only for IFSU but also for the Cordillera Administrative Region. We give our commitment not only to be good stewards of this center…we will strive to deliver impactful solutions,” she remarked.

The M&E Innovation Center in IFSU is equipped with industrial-grade metalworking machinery, including a hydraulic shearing machine, sheet metal roller, and lathe machine. These resources will be accessible not only for academic purposes but also for local industry use. Students can utilize the facility for thesis projects, while other state universities and colleges are encouraged to collaborate with the Center on research and development activities.

Local businesses can benefit from the facility through a time-sharing scheme, and local equipment fabricators are invited to engage in contract research or joint research activities. This Innovation Center aims to be a hub where university researchers, industry professionals, community leaders, and other stakeholders can come together to address pressing local issues through collaborative research.

During the ceremony, the project team presented their completed R&D projects, including a coconut grater with a presser, a coconut dehusker, and a vegetable slicer machine. These technologies are now being utilized by their beneficiaries, showcasing the tangible impact of the Center.

The handover ceremony underscores a robust partnership between DOST, DOST-MIRDC, and IFSU, and encourages the community in the Cordillera Administrative Region (CAR) to transform ideas into innovations. From innovations, communities in the CAR can create value, generate jobs, and boost economic activities. Wide utilization of this Innovation Center will also strengthen collaborative relationships among the academe, industry, and government.

For more information and to explore collaboration opportunities, please contact This email address is being protected from spambots. You need JavaScript enabled to view it..

DOST’s AMCen Launched as the Third Advanced Manufacturing Institute: Towards an Industry 4.0-Ready Filipino Workforce

by Faith P. Macatangay

“AMCen’s vision to become a leading hub of additive manufacturing and rapid prototyping aligns perfectly with USAID’s mission to develop a highly skilled workforce for this innovative sector,” USAID Acting Mission Director Betty Chung shared about the launch of AMI in the metropolis.

The Advanced Manufacturing Workforce Development Alliance (AMDev) Program, under the partnership of Unilab Foundation, Inc. (ULF) and the United States Agency for International Development (USAID) Philippines, formally launched Department of Science and Technology-Metals Industry Research and Development Center‘s (DOST-MIRDC) Advanced Manufacturing Center (AMCen), as the country’s third Advanced Manufacturing Institute (AMI) on July 29, 2024, at the DOST-MIRDC Compound, Taguig City.

Officials from the ULF, USAID, AMDev, Department of Trade and Industry (DTI), and DOST during the unveiling of the AMDev marker located at the AMCen Building.

AMI is one of the flagship initiatives of the AMDev program. These institutes, established through collaborative partnerships, will serve as a learning hub that will prepare the Filipino manufacturing workforce for the fourth industrial revolution.

Atty. Jose Maria Ochave, Executive Director of ULF, emphasized the goals of the partnership, “By uniting AMDev’s vision of accessible innovation hubs with DOST-MIRDC’s extensive resources and network, we hope to forge a path toward a future-proof workforce.”

AMCen is the Philippines’ first technological hub for additive manufacturing or 3D printing. As an AMI, the Center will provide training programs on additive manufacturing to 11,000 people who are currently employed or will be employed in the manufacturing industry.

During the event, AMCen Steering Committee member Dr. Rigoberto Advincula introduced the pilot batch of 23 trainees. Their training on emerging technologies commenced right after the launching program.

Engr. Noilan S. Santiaguel from TDK Philippines Corporation stated his expectations for the training, “Isa sa mga functions ko is to do factory innovation. Pinadala ako to learn new ways to do manufacturing.”

Secretary Renato U. Solidum, Jr. also stated DOST’s full support to the AMI’s initiative, “In addition to pursuing the enhancement of skills of the workforce, AMCen as the newest AMI, will also focus its attention to materials R&D, prototyping and fabrication, collaborations and partnerships, technical services, training services, and policy standards. As such, AMCen is going to be the one-stop solution center for additive manufacturing concerns of the industry.”

DOST-MIRDC Executive Director Robert O. Dizon added, “As agents of positive change, clients and stakeholders rely on us and look up to us for direction to set a clear path. The path that we will create is the one that is sure to lead us to increased productivity and competitiveness.”

Attendees from the industry, academe, media, and government during the AMDev – DOST-AMCen AMI Launch at the DOST-MIRDC Compound, Taguig

For detailed information about the latest technologies, services, and collaborative activities of the DOST-MIRDC, like and follow our DOSTMIRDC Facebook page and visit our website www.mirdc.dost.gov.ph.