The Metals Industry Research and Development Center (MIRDC) is preparing for the grand celebration of its golden founding anniversary on June 18, 2016. The key officials of the MIRDC are looking forward to a robust participation not only of the MIRDC personnel but also of the metalworking industry associations and other stakeholders.

MIRDC 50th logo

With this longevity, sustaining power and success, the Center’s customers could look forward to more aggressive products and services that the MIRDC could efficiently and effectively provide.

To kick off the celebration, a contest was launched among MIRDC employees for the best anniversary logo. The winning

entry, now the official anniversary logo, appears in all written correspondences of the Center. With less than 30 days before the celebration, various committees are carrying out activities for the highlights of the anniversary, namely: the monument construction; M&E international conference; thanks-giving dinner; homecoming for former MIRDC officials and employees; physical landscaping; special publications that will be launched; and the construction of the new main access road and MIRDC gate.

Dr. Agustin M. Fudolig, Deputy Executive Director for Technical Services, chairs this year’s over-all M & E Week and 50th Anniversary Celebration.

Happy, blessed, fruitful golden anniversary M I R D C !

|

Perspective photos of the MIRDC main laboratory building, reception lobby and main gate |

The Metals Industry Research and Development Center, an agency of the Department of Science and Technology, is assisting the Whittlers Arts and Crafts of Pakil, Laguna through the deployment of a new technology - the CNC router. The Whittlers designated some of its employees undergo training on how to operate and maintain the machine that will be used to produce its various products. The CNC router or Super Lilok is one of the machines recently developed by MIRDC in partnership with a private company – Primark Toolings, Inc. - to help the furniture industry to meet the requirements for consistent quality thus, attaining global competitiveness.

With the introduction of the technology from MIRDC, Whittlers is expected to increase its productivity and consistently enhance product quality. Engr. Jason P. Rogelio, MIRDC project leader, leads the training of Whittlers personnel for the operation of the CNC router. The training program was held on March 1-3, 2016 covering maintenance and operation. Engr. Adonis T. Marquez from the Technology Diffusion Division coordinated the activity. Whittlers’ Art uses knives of various thicknesses and lengths to shave soft wood, transforming the shavings into filigreed fans, peacocks, butterflies, birds, flowers, and other designs of various shapes and sizes.

|

|

|

MIRDC staff conducts training to Whittlers for the operation |

Manually-made products of Whittlers |

The CNC Router or Super Lilok is a machine that is operated by G-codes. The controller reads the G-codes and translates the numbers to mechanical movement so that it can cut and engrave on woods, metals and acrylics. This machine can mass produce more intricate and sophisticated designs. This was developed by MIRDC to help the local wood-working and metal-cutting industries stay competitive.

Whittler’s Arts and Crafts of Pakil is located at 175 Tavera street, Pakil, Laguna.

|

| Whittlers personnel operates the CNC router machine under supervision by MIRDC staff |

"Molding the Future of Metal Industries"

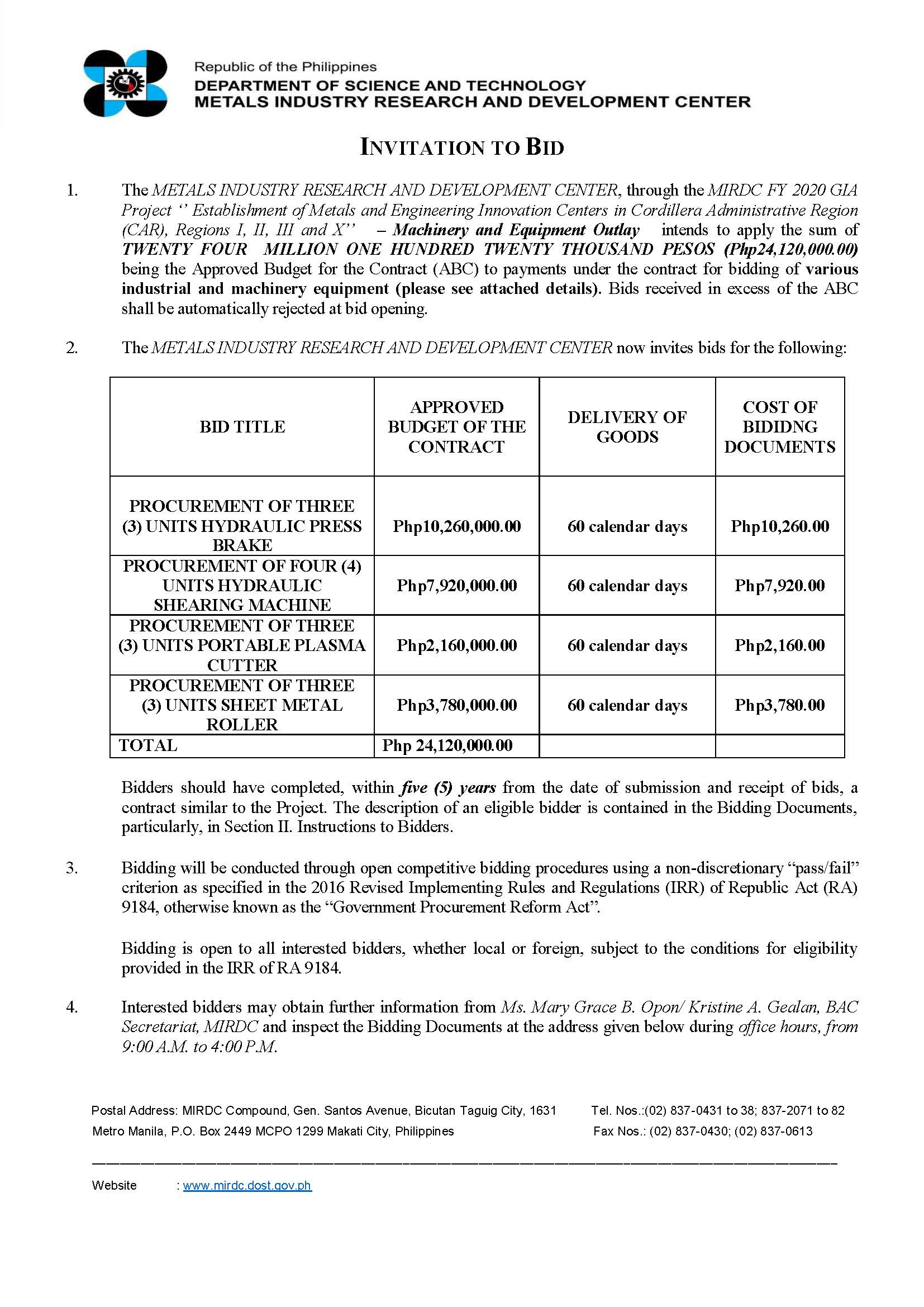

For further information, please refer to:

Sgd.

Ms. Aurea T. Motas

BAC Chairman

Metals Industry Research and Development Center

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel. No. 837-0431 local 442 and 444

"Molding the Future of Metal Industries"

MANDATE

The Metals Industry Research and Development Center (MIRDC) provides both the government and the private sector in the metals and engineering industry with professional management and technical expertise on training of engineers and technicians, information exchange, trade accreditation services, quality control and testing of metal products, research and development, and business economics advisory services.

VISION STATEMENT

"Center of excellence in science, technology and innovation for globally competitive metals, engineering & allied industries by 2025."

MISSION

“To provide both government and private sectors in the metals, engineering, and allied industries with professional management and technical expertise on the training of engineers & technicians; information exchange; quality control & testing; research & development; technology transfer; and business economics advisory services.”

CORE VALUES

The set of Core Values, easily referred to as PRIDE, is defined as follows:

Professionalism

- We adhere to the highest ethical standards of performance

- We value our work and committed to perform to the best of our ability

Responsiveness

- We spearhead implementation of projects that address the needs of the metals and engineering industry

- We find solutions to real-life problems through science, technology and innovation

Integrity

- We act responsibly, work honestly, and encourage transparency

Dynamism

- We perform our jobs with vigor and enthusiasm

- We welcome change as an opportunity for growth and continual improvement

Excellence

- We adhere to world-class performance and continuous improvement in all we do

- We always do our best in every task/endeavour